As with architectural panels, insulated sandwich wall panels can be strictly architectural, strictly structural or a combination. They can be placed in either a horizontal or vertical position depending on the project’s needs.

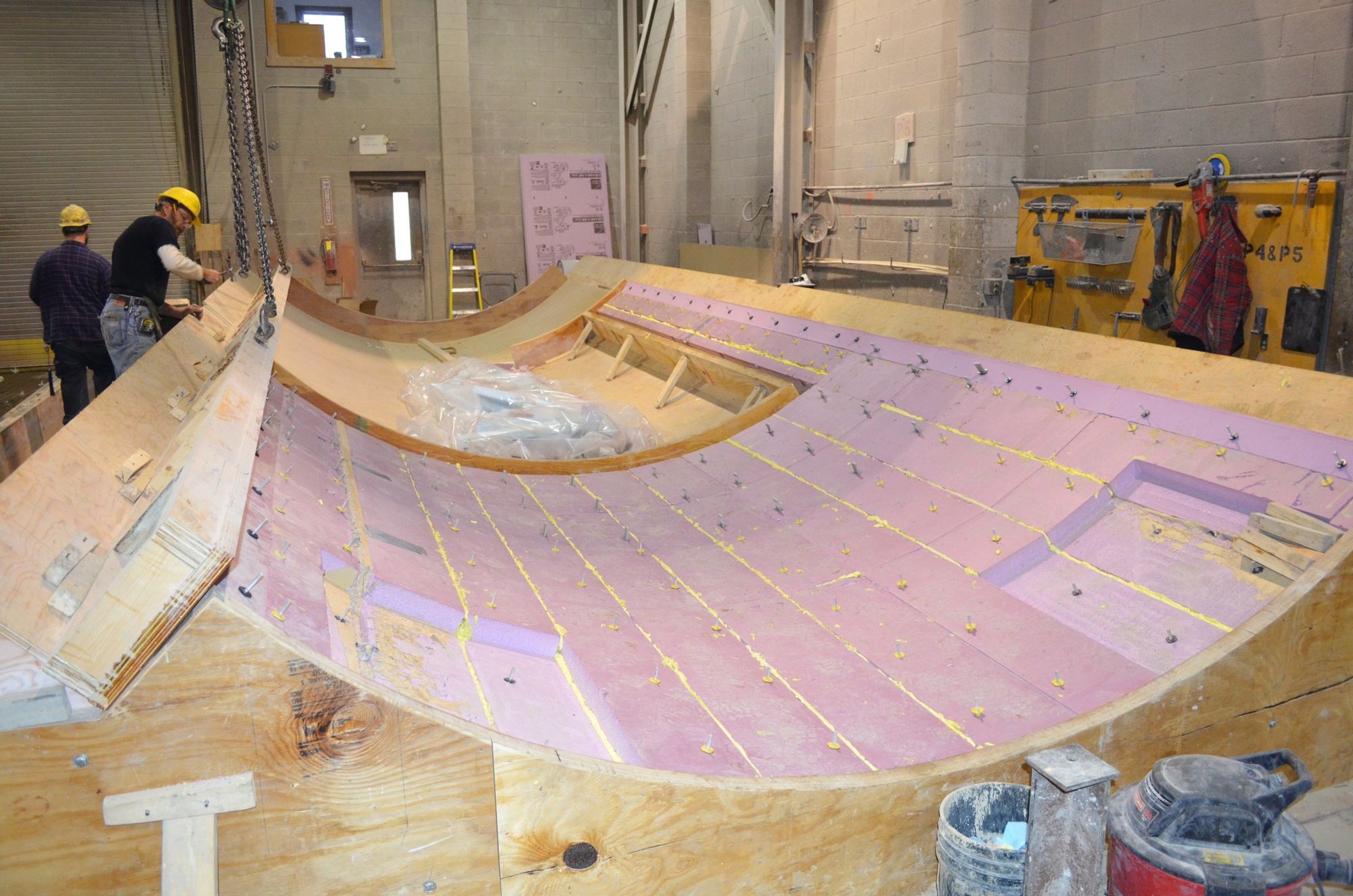

The “sandwich” portion of the name refers to a layer of rigid insulation cast between two wythes of concrete (“sandwiched” between them). The type and thickness of the insulation depends on the thermal efficiency desired and the specific precaster’s production methods.

Two types of panels can be created, composite or non-composite. Which type is fabricated depends on the configuration and material used for the ties. Composite panels connect the two wythes of concrete without penetrating the insulation with a conductive material. This allows the structural performance to be based on the full thickness of the panel. In non-composite panels, the wythes are connected using ties through the insulation, which limits performance to the individual capacities of each wythe.

Insulated sandwich wall panels can be designed to be load-bearing to support floor and roof components. For this application, they are cast with a thicker interior wythe to provide the necessary support for beams. They also can be nonload-bearing to complete a façade.

As with typical wall panels, the panels are cast in a flat orientation, so the form side is usually the side that will be exposed to view in the final construction. This face can be made with virtually any type of finish. The back face is typically troweled smooth or may have a light broom finish. In most cases, the interior does not need additional furring and drywall to create the finished surface unless desired.